Stability chambers are used for testing products and also to evaluate their shelf life like electrical components, industrial accessories, drugs, etc. It enables the researchers to modify parameters like humidity and temperature to conduct a rigorous check over diverse conditions. Without a doubt, various products require different conditions for testing but it’s practically impossible to roam around the place to experience different climate conditions. This is where stability chambers come in handy and make the job easier for researchers. With these systems in place, researchers can track changes that transform the product quality during instances of alternating environmental exposure.

Types of stability chambers

Generally, stability chambers are of two types as listed below:

- Reach in Chambers: They are small in size and are implemented for testing small quantities of product. One of the prime benefits of using these chambers is their convenience.

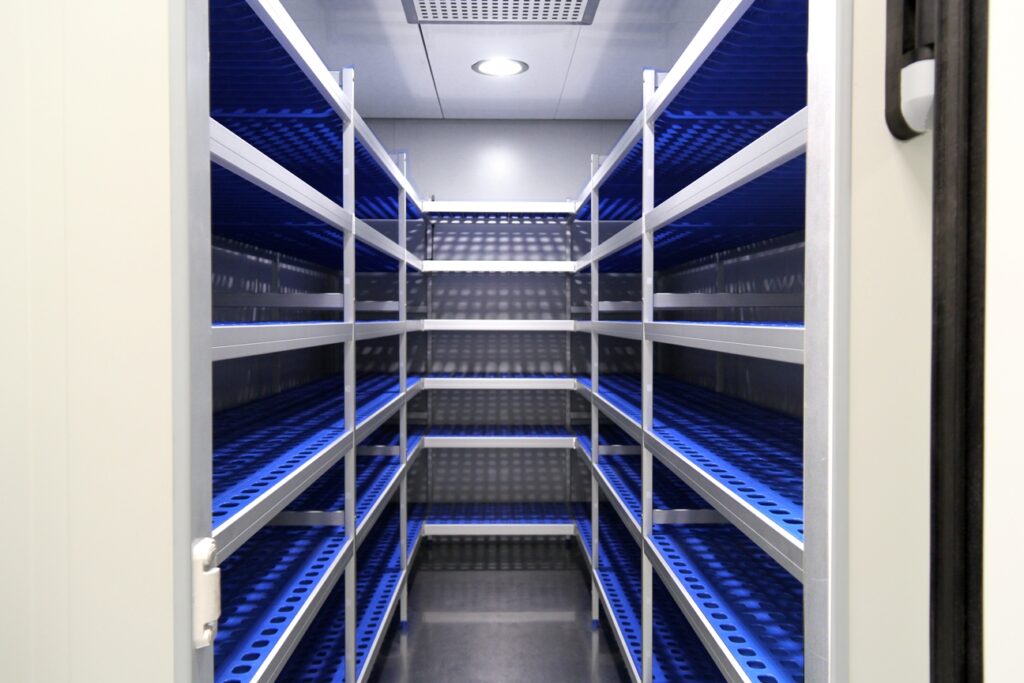

- Walk-in Chambers: As the name highlights, these chambers are larger in size and you can walk into them. They are used for testing larger batches of items that demand exact conditions for a long period. Walk-in chambers are implemented to record product performance in the following conditions:

- Moisture/humid conditions

- Rainy conditions

- Dry regions

- Exposure to the sun

- Increased temperature conditions

- Significant environmental changes

Besides these two, there are other types of chambers, though not very popular in the real world:

a) Environmental Chambers

b) Accelerated testing chambers

c) Temperature-Humidity chambers

d) Photostability chambers

Functioning of stability chambers

The working of these chambers is grounded on a simple principle, i.e., by maintaining a standard temperature, a steady value of relative humidity will also be maintained. Simplistically, relative humidity is the ratio of current water proportion in the air and how much it can hold at its optimum. When the temperature is increased, the capacity of water that air can hold increases. At the same time, the relative humidity decreases by a significant margin. In this way, both the parameters are modified simultaneously.

All stability chambers adhere to the ICh regulations that state the temperature mustn’t be deviated by more than two to three degrees, and the humidity should not change by more than 5%.

The inner and outer body is constructed out of corrosion-resistant stainless steel. The inner body is also lined with proper insulation. The chamber comprises a number of shelves for placing the item that can be quickly removed. Sensors are attached to these chambers for identifying temperature and humidity levels. Horizontal laminar airflow is the preferred option for more accurate uniformity of required conditions. With this system in place, the shelves will receive a consistent airflow even when they are fully loaded with samples. The presence of attached blowers maintains the proper circulation of air. Data loggers are also present for receiving and transmitting information.

Applications of stability chambers

There are extensive uses of stability chambers. They are critical when it comes to the completion of manufacturing a certain product. For this reason, it has wide uses in the automotive industry, pharmaceutical industry, packaging, cosmetic industry, research work, biological or microbiological tests, etc.

There are various types of stability chambers available in the market. However, you need to choose the right one for your needs. In case of any guidance, it’s always advisable to consult an expert rather than making all the decisions yourself.

Are you looking to buy high-quality stability chambers to meet all your research needs? If you sense so, www.igenels.com is the right place to be in. On this website, you get access to top-notch laboratory equipment without burning a hole in your pocket.