Laminar flow hoods, also known as laminar flow cabinets, are essential equipment in laboratories, providing a sterile environment for various scientific procedures. This blog will explore the components, working principles, types, and uses of laminar flow hoods, along with the necessary precautions for their use.

Table of Contents

Components/Parts of Laminar Flow Hood

1. Cabinet

Principle/Working of Laminar Flow Hood

Procedure for Running the Laminar Flow Cabinet

Types of Laminar Flow Cabinet

1. Vertical Laminar Flow Cabinet

2.Horizontal Laminar Flow Cabinet

Uses of Laminar Flow Hood

Precautions

References and Sources

Components/Parts of Laminar Flow Hood

1. Cabinet

The cabinet forms the main body of the laminar flow hood, typically made from stainless steel or another non-corrosive material. It houses all the other components and provides a sterile environment for the working station.

2. Work Station

The working station is the area inside the cabinet where the actual work is performed. It is designed to be spacious and easily cleanable, ensuring that materials and samples remain uncontaminated.

3. Filter Pad/Pre-filter

The pre-filter captures larger particles and debris from the air before it passes through the HEPA filter. This prolongs the life of the HEPA filter and maintains the efficiency of the system.

4. Fan/Blower

The fan or blower draws air through the pre-filter and pushes it through the HEPA filter. This creates the laminar flow of clean air over the working station.

5. UV Lamp

A UV lamp is used to sterilize the interior of the cabinet when it is not in use. The UV light kills any microorganisms present, ensuring that the work area is sterile before starting any procedure.

6. Fluorescent Lamp

Fluorescent lamps provide illumination for the working station. Proper lighting is essential for accuracy and precision in laboratory work.

7. HEPA Filter

The High-Efficiency Particulate Air (HEPA) filter is the most critical component. It removes 99.97% of particles that are 0.3 microns or larger from the air, ensuring a clean, particle-free environment within the cabinet.

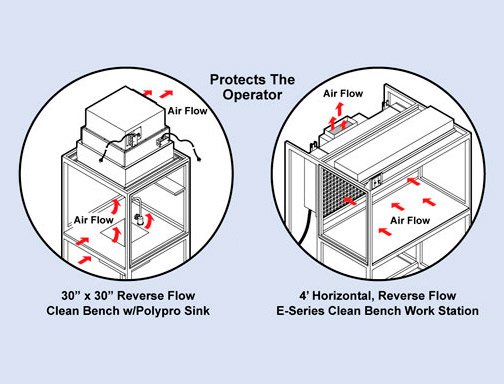

Principle/Working of Laminar Flow Hood

The laminar air flow hood operates on the principle of creating a continuous, unidirectional flow of HEPA-filtered air. The blower pulls in ambient air through the pre-filter, trapping large particles. This air then passes through the HEPA filter, which removes nearly all remaining particles. The clean, filtered air flows in a uniform direction over the working station, preventing contaminants from entering the sterile workspace.

Procedure for Running the Laminar Flow Cabinet

1. Preparation: Ensure the cabinet is turned off. Clean the working station and all materials to be used with a disinfectant.

2. Sterilization: Turn on the UV lamp and close the sash. Allow the UV light to sterilize the interior for 15-30 minutes.

3. Setup: Turn off the UV lamp, then turn on the blower and fluorescent lamp. Let the blower run for a few minutes to purge the cabinet of any remaining contaminants.

4. Operation: Perform your work within the sterile area. Avoid introducing contaminants by moving materials in and out of the hood carefully.

5. Shutdown: After completing your work, clean the working station again. Turn off the blower and fluorescent lamp. If desired, turn on the UV lamp for further sterilization.

Types of Laminar Flow Cabinet

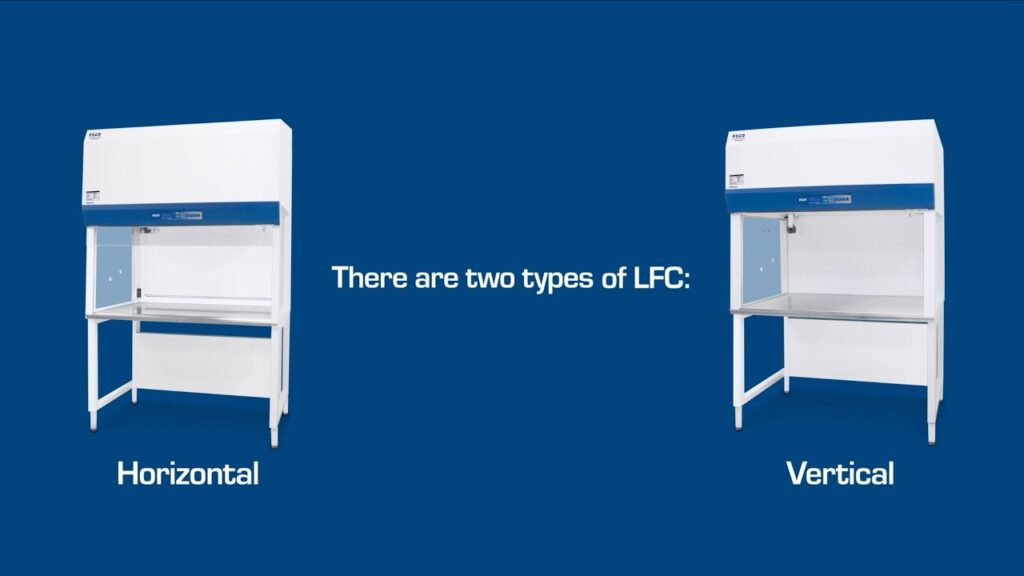

Vertical Laminar Flow Cabinet

In vertical laminar flow cabinets, air flows from the top of the cabinet down to the work surface. This type is particularly effective in protecting the user and the environment from contaminants generated within the cabinet.

Horizontal Laminar Flow Cabinet

In horizontal laminar flow cabinets, air flows from the back of the cabinet towards the user. This configuration provides a sterile environment over the work surface but does not protect the user from contaminants generated within the cabinet.

Uses of Laminar Flow Hood

Microbiological Research: Provides a sterile environment for handling cultures and preventing contamination.

Pharmaceuticals: Ensures sterile conditions for the preparation and packaging of medications.

Electronics: Prevents contamination during the assembly of sensitive electronic components.

Tissue Culture: Provides a clean environment for culturing tissues and cells.

Food Industry: Used for microbiological testing to ensure food safety.

Precautions

Personal Hygiene: Always wash hands and wear appropriate PPE before using the hood.

Sterilization: Regularly sterilize the interior of the cabinet with UV light and disinfectants.

Proper Handling: Move hands and materials slowly to avoid disturbing the laminar flow.

Regular Maintenance: Replace pre-filters and HEPA filters as recommended by the manufacturer to ensure efficient operation.

Avoid Overcrowding: Do not overcrowd the working station, as this can disrupt the airflow and compromise sterility.

References and Sources

Laminar Flow Hood. ScienceDirect, Elsevier.

Understanding Laminar Flow Hoods. Laboratory Equipment Magazine.

HEPA Filters and Their Uses in Laboratory Equipment. American Society for Microbiology.

Sterilization Techniques for Laminar Flow Cabinets. Journal of Laboratory Automation.

Maintenance and Care of Laminar Flow Hoods. Lab Manager Magazine.

By understanding the components, working principles, and proper usage of laminar flow hoods, laboratory personnel can ensure a sterile and safe environment for their critical work.